I designed automatic self driving vehicles in 1963. E-mail me on don@tyzack.net if you have a comment or a question. |

Robotug |

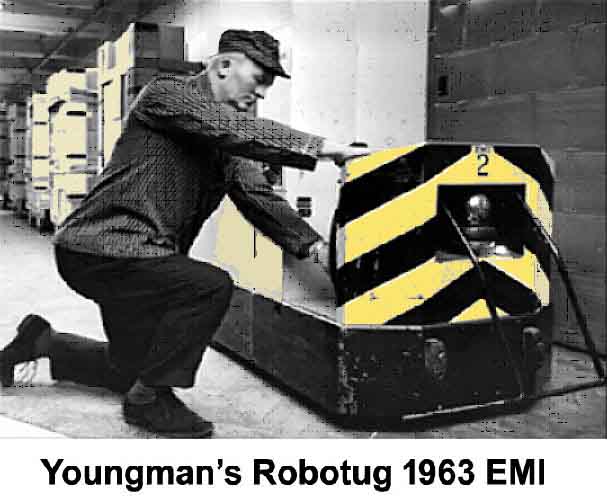

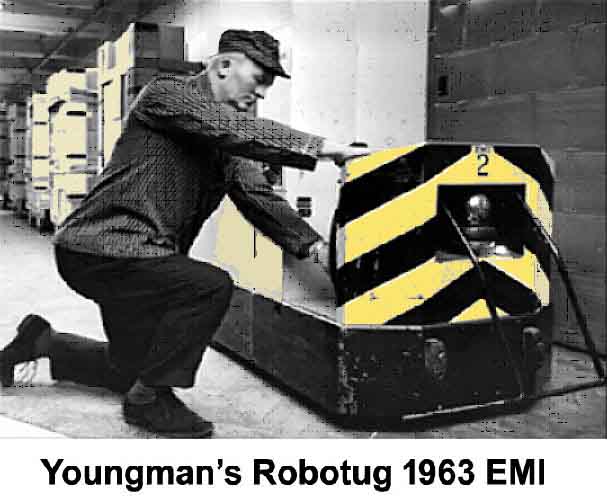

| Self Driving Vehicles Machine tools weren't the only automation devices on which I worked in 1963. The next laboratory to mine contained a group who designed Robotugs, which were small self steering tugs. This new group with their untried design, had just won a big order and had completed the installation of a 40 tug system in GKN's nut and bolt warehouse at Darleston. They had only been allowed to work at night when the warehouse was not in operation. The system was launched one night after working hours, when all the big wigs, (Managing Directors), were invited to see the launch. All went well at first and then in a distant corner of the warehouse there was a bang. Soon after there was another and before long the whole warehouse was like a battlefield. The reason for the bangs was that the electronic circuits controlling the tugs had been designed so that they only just worked. For example if the tug was going around a bend whilst picking up a control signal, it might drift a bit off the line and so pick up say 80% of the control and thus drift off more and finish by leaving the track. Additionally similar marginal design happened with the emissions which were supposed to tell it when to stop. I was not there so I do not know what was said at the time. I do know that the EMI managing director, Clifford Metcalf, was extremely embarrassed. Next day I was summoned into my boss Dick Booth's office. "Mr X is no longer head of the Robotug group." I was told, (I leave his name out because he was just the scapegoat.) "We want you to take over as manager!" So, as my first management job I became Mr Robotug. It took my team about six months to fix all the problems which were all due to marginal design. I redesigned their original transistor amplifiers with lots of feedback. This technique ensured that the amplifying devices, (transistors), could degrade and almost die before they affected the overall tug's performance. All work at Darlington, (the GKN warehouse), however had to be done at night and the return car drive was down the then newly built M1 with no other traffic at 4am in the morning. It was at that time a very dangerous thing to do. One would pull in to each service station, take a cup of coffee and then return to the completely empty motorway and drive into the pitch darkness ahead. I kept all windows open but nothing helped to keep one awake. Eventually by the fourth cuppa I decided to try tea and that worked: no more sleep that night each time. This was all around 1963 and by then we had perfected a reliable self steering Robotug system. In addition to the original tugs themselves another company, Youngmans, designed a further vehicle for us to control. Both tugs from then on performed very well and were sold to a lot of warehouses and other operations. As self steering vehicles seem to be getting into the news these days, including the surveys carried out by the AA, I cannot understand why our tugs were not used more widely. I feel it was probably a lack of marketing effort as our sales force had many other things to sell such as our successful but competitive Stacker Cranes which we designed. Other companies also began to copy our products. I remember we sold one tug to a Japanese company. We normally expected most sales to be followed by a request for an engineer to follow up for the installation. In this case we never heard another thing except that later a Japanese company started selling an almost identical product. | |

Please Note: we are in contact with a museum which wants to exhibit a Robotug. If anyone has one, (obviously one not in use), I would be please to put you in touch with them. |

Robotug |